SL LASER IS CONSIDERED ONE OF LEADING MANUFACTURERS OF LASER PROJECTION SYSTEMS WORLDWIDE.

More than 10,000 installed devices are in use day after day in a variety of industries and countries. Craftsmen and large companies use the projectors to simplify and speed up their work processes, reduce costs and at the same time improve the quality of their products with the highest precision.

SL Laser’s devices and software enable them to realize significant competitive advantages in this way – and have been doing so for over 30 years.

At SL Laser, we have always placed great emphasis on the user-friendly operation and self-explanatory functionality of our laser projectors, measurement systems and positioning lasers. Developed by practitioners for on-site users, the systems enjoy great acceptance. The installation on trial and the well-founded introduction by our employees enable a quick and risk-free changeover to the new technology. A close-knit distribution network with sales partners all over the world allows excellent service. Test us. At SL Laser, your success is the benchmark for our thinking!

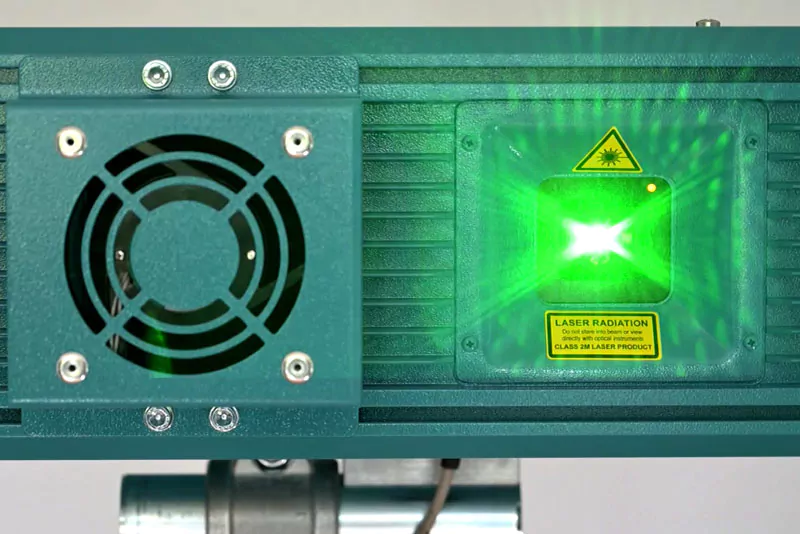

Laser projectors – Laser projection systems.

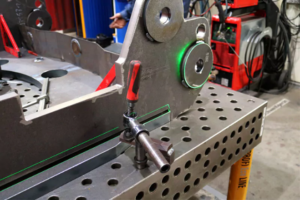

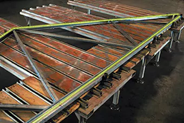

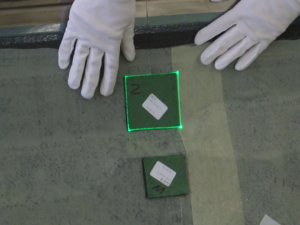

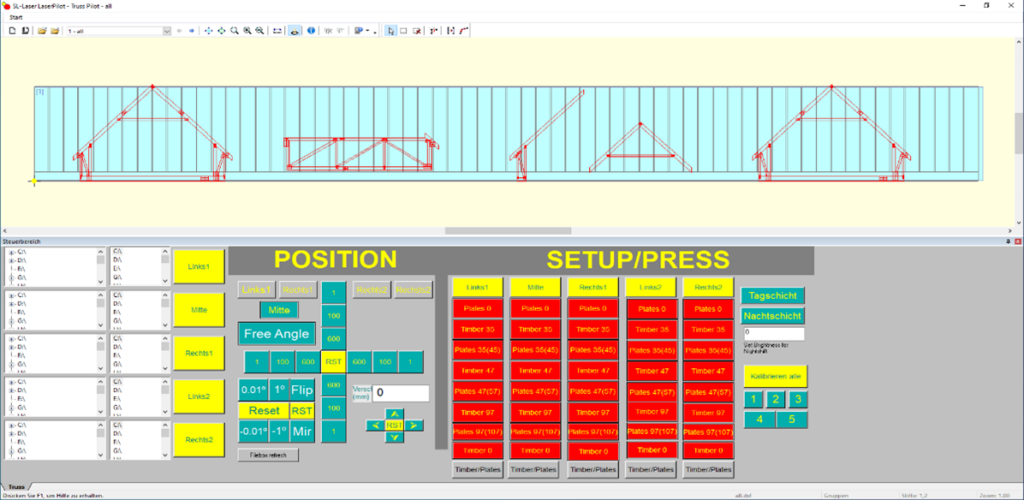

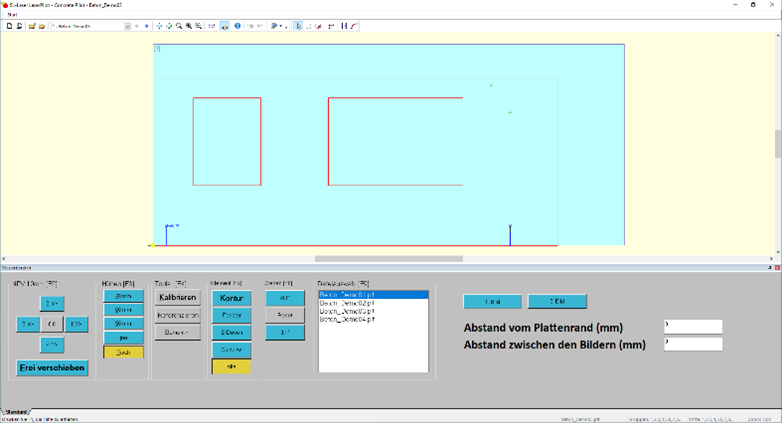

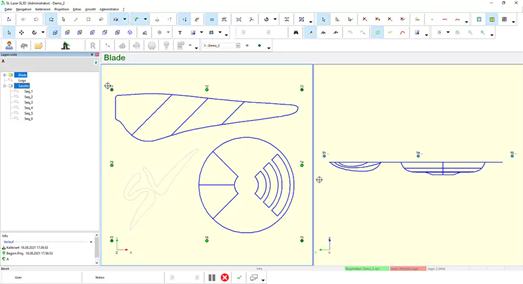

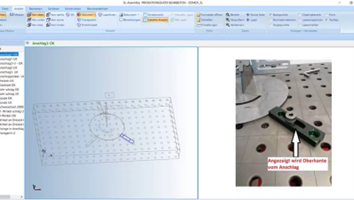

Today, laser projection in industry means above all time savings, material savings and error minimization. Worldwide, manufacturing companies in almost all industries work with laser projectors from SL Laser. They save the expensive use of templates by having the work on the workpiece or on the table aligned directly with the guidance provided by the laser beam. This increases the precision of the work considerably and also facilitates quality control.

Thus, the investment in one of the laser projection systems from SL Laser has usually paid for itself after a very short time and not only generates profit, but also an advantage over other companies in the industry. In the same way, aircraft manufacturers or the aerospace industry also work with laser projection in very confined spaces and thus ensure the necessary highest precision.

Laser projectors from SL Laser

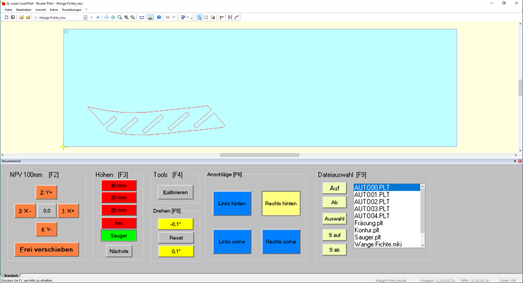

Since the first laser projectors were developed at SL Laser more than 30 years ago, we have continuously improved the technology and made it easier to use. In combination with the self-explanatory operator software, the handling of the SL Laser projectors can be learned in a very short time.

After a quick start-up phase, colleagues at the machines also swear by the SL Laser Projectors.

The optical laser guidance system on the CNC milling machine, the nailer binder projection or the cross projection for drilling saves a lot of tedious work with the template and the re-alignment of the workpieces. But most of all, it saves the frustration of otherwise inevitable mistakes. Our popular offer of a test installation and introduction to a laser projector from SL Laser regularly proves to be a sensible investment for us as well. In most cases, the installation is simply taken over. Conviction through performance.