NC-HOPS

THE COMPLETE CAD/CAM PACKAGE.

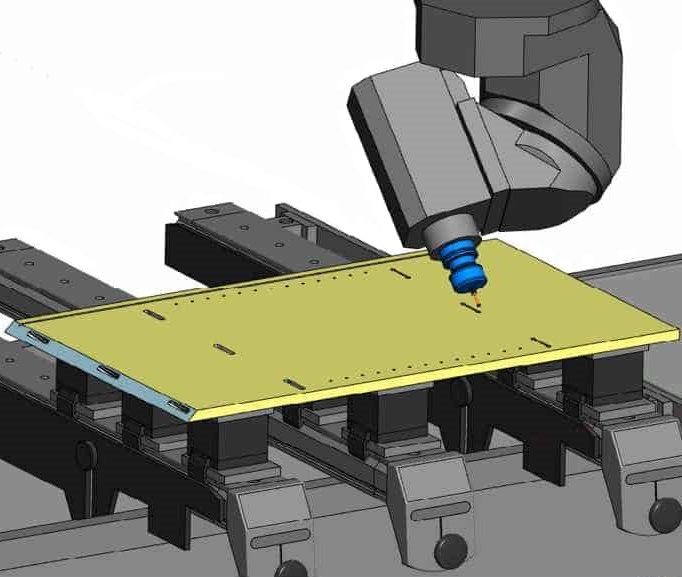

NC-HOPS: CAM system for wood, plastic and aluminum production. Initially conceived as a wood-oriented programming system, the extensive variant technology and flexibility meant that it was also quickly used in plastics and aluminum processing.

CAD/CAM-package with variable macro technology.

With NC-HOPS as CAD/CAM solution, the visual development of dynamic components is possible in a very short time. This maximizes productivity and ensures a fast path to the finished product. Powerful macro technology and the always up-to-date graphical display support the user in creating fixed or variable components.

Key advantages:

- Machine-independent software.

- Quick and easy input in dialog with EasySnap function.

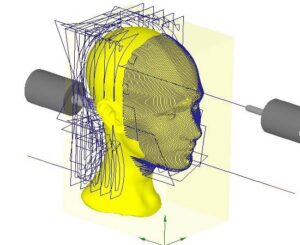

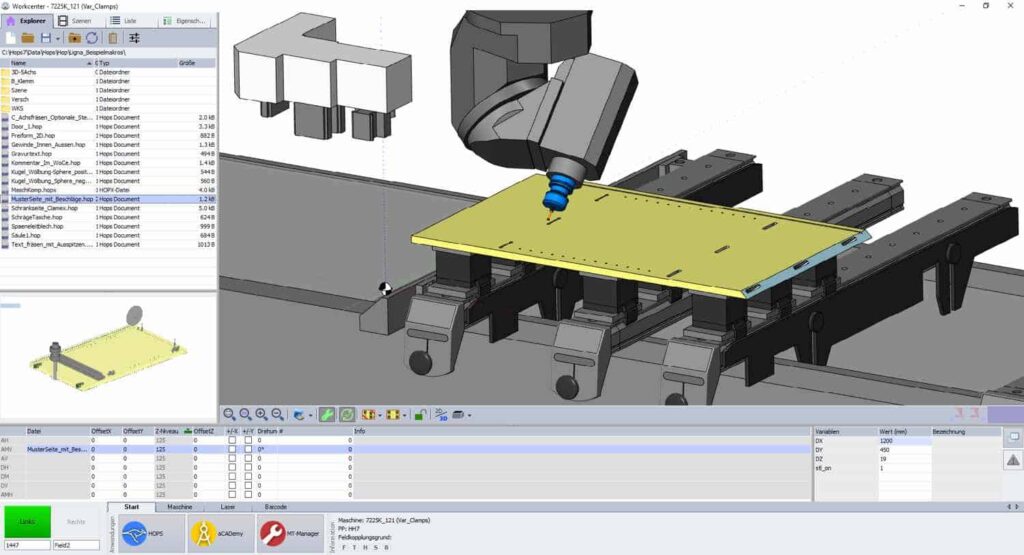

- Spatial 3D Visualization & Simulation.

- Flexible library concept.

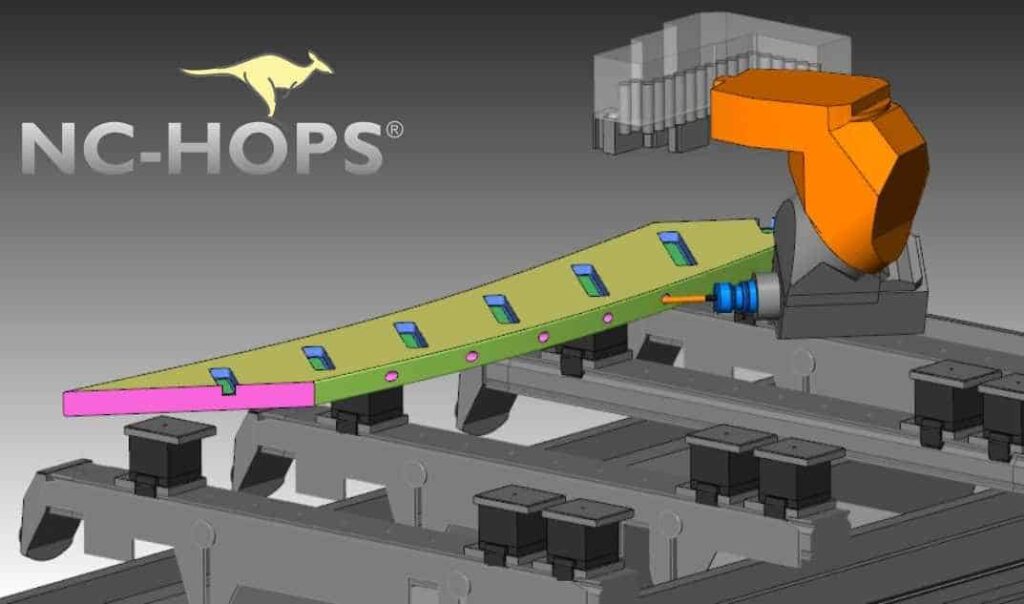

- Support up to 5 axes and Multihead.

- Intelligent postprocessor concept.

- Integration into existing environment.

- Partner of all leading machine manufacturers.

Software

NC-HOPS was conceived in the beginning as a wood-oriented programming system,

NC-HOPS was conceived in the beginning as a wood-oriented programming system,

but was also very quickly used in plastics and aluminum processing due to its extensive variant technology and flexibility.

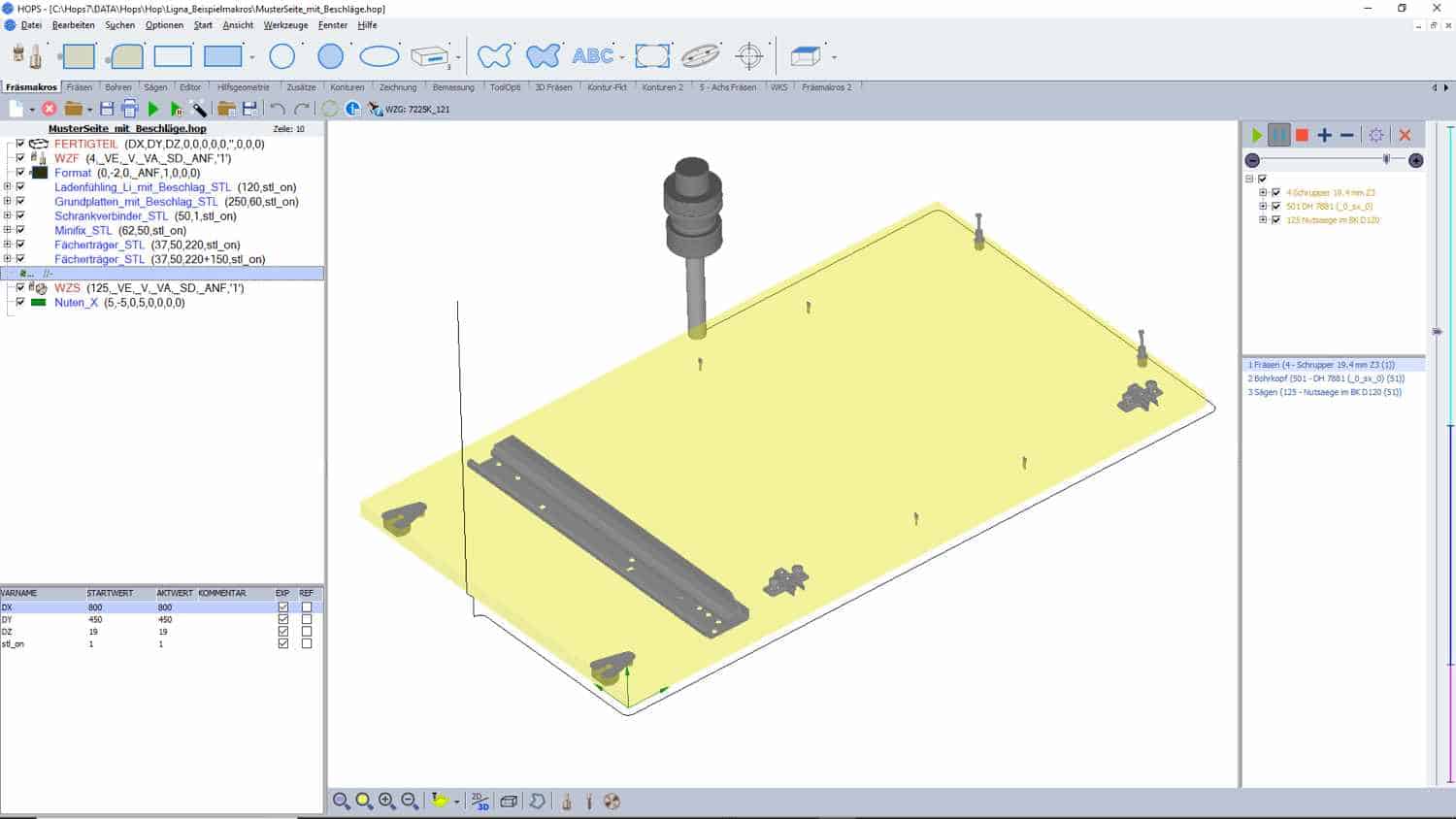

Tool-specific safety distances, approach distances and feeds guarantee a high level of safety. The integrated 3-D view shows traverse paths, the tool position and clearly displays the entire workpiece. The workpiece can be rotated to any desired view at the click of a mouse. The machine-independent machining strategies are reliably translated by the system into the language of the respective control types.

Some areas of application of NC-HOPS:

- CNC furniture production

- CNC interior fittings

- CNC door production in leaf and frame production

- CNC staircase production

- CNC window construction

- CNC facade construction

- Interior fittings for ships and yachts

- Truck trailer and caravan production

- Acoustic components

Flexible Library Concept

Flexible Library Concept

A flexible library concept guarantees the constant expansion of your own workflows and complete components. Due to the machine-neutral workpiece description, no time-consuming approach and retract movements, positioning sequences and special functions have to be programmed on the machine. The conversion of the drawing data into the CNC machine language takes place in a mature post-processor concept. Minimized machining times are achieved by drilling optimization, tool change and travel path optimization.

NC-HOPS is absolutely Windows-oriented, and therefore easy to learn and safe to use.

NC-HOPS is absolutely Windows-oriented, and therefore easy to learn and safe to use.

As an innovative, powerful program, NC-HOPS gives the user the possibility to design his product creatively and easily. Registers group the functions into machining groups. This makes it possible to quickly find the required machining operations. Extensive functions and the possibility to expand with your own macros offer optimal integration into the production process.

Optional Modules

The flexible library concept guarantees continuous expansion of workflows and complete components.

The machine-neutral workpiece description means that no time-consuming approach and retract movements, positioning sequences and special functions have to be programmed on the machine.

The conversion of the drawing data into the CNC machine language takes place in a mature post-processor concept.

This maximizes productivity and ensures a fast path to the finished product.

Powerful macro technology and the always up-to-date graphical display support the user in creating fixed or variable components.

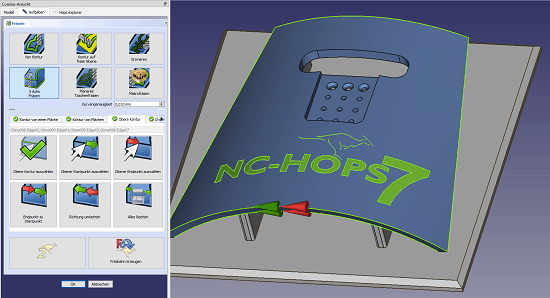

4SOLID® FOR NC-HOPS7 – EASY MILLING OF SHAPES!

4SOLID® FOR NC-HOPS7 – EASY MILLING OF SHAPES!

4SOLID® completes the NC-HOPS package for the all around user with free form and surface processing.

The import of STL, STEP or IGES surface data from any construction program allows the processing definition of rough and fine milling using 3+2 Axis.

Without the need to learn another CAD or CAM application the surfaces are getting imported in NC-HOPS 4SOLID®. Extensive manufacturing strategies calculate fast the requested result.

aCADemy FOR NC-HOPS

aCADemy FOR NC-HOPS

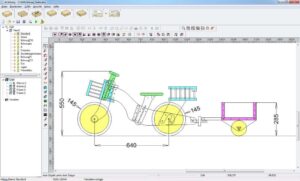

With aCADemy you get a full 2D CAD with the possibility of free construction or the import of DXF and AutoCAD® DWG drawings.

These can be easily reworked and directly linked to NC machining cycles in the drawing. Of course, multi-sided machining is also possible.

Calling variant macros combines variant technology and CAD/CAM functionality for fast transfer to the machine. By using Frag&Drop, the machining operations can be brought into the desired sequence.

BETTERCAM

BETTERCAM

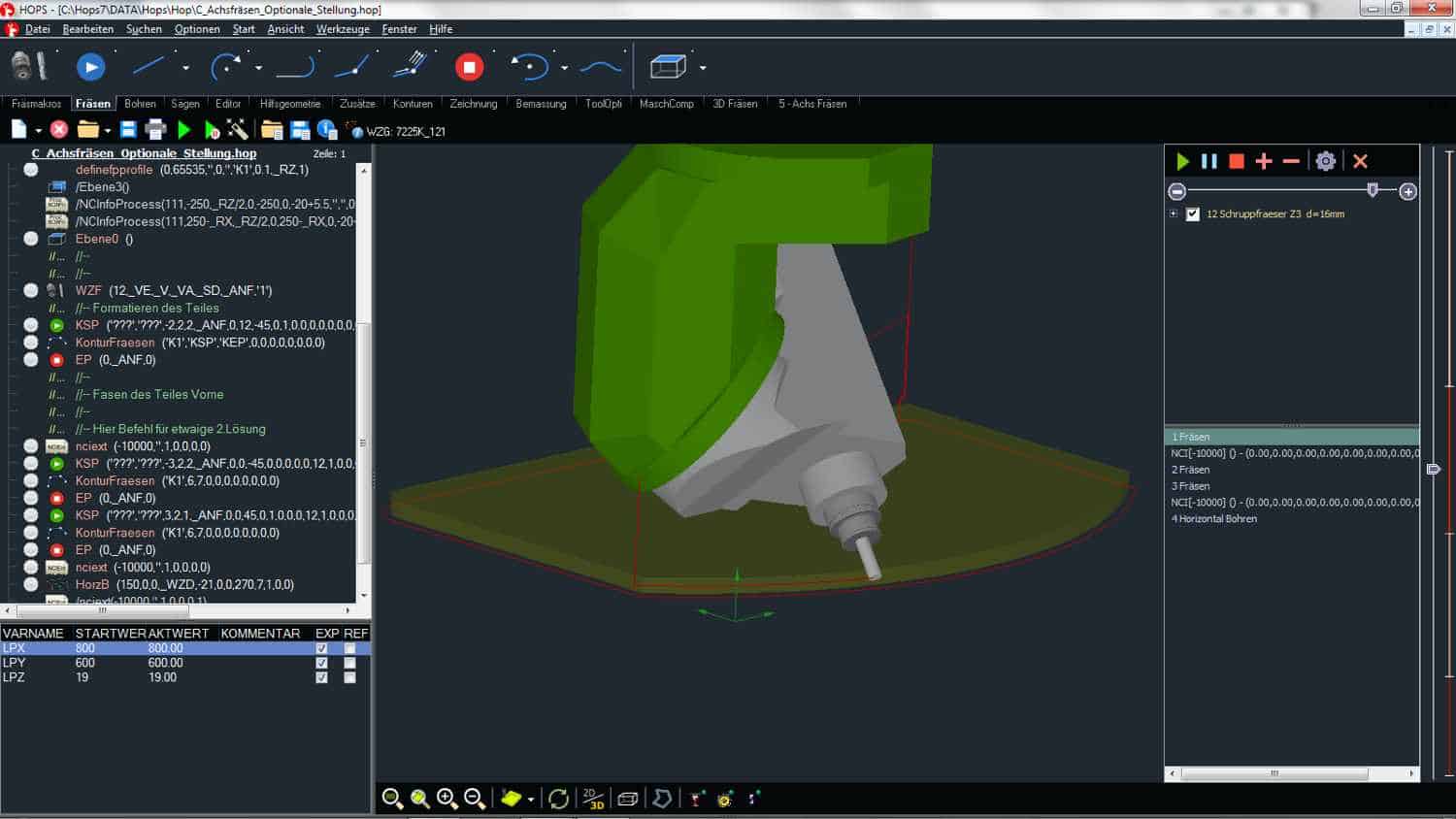

With BETTERCAM® you can easily define your NC machining on 3D Solid. You are supported by a feature recognition and clear menus.

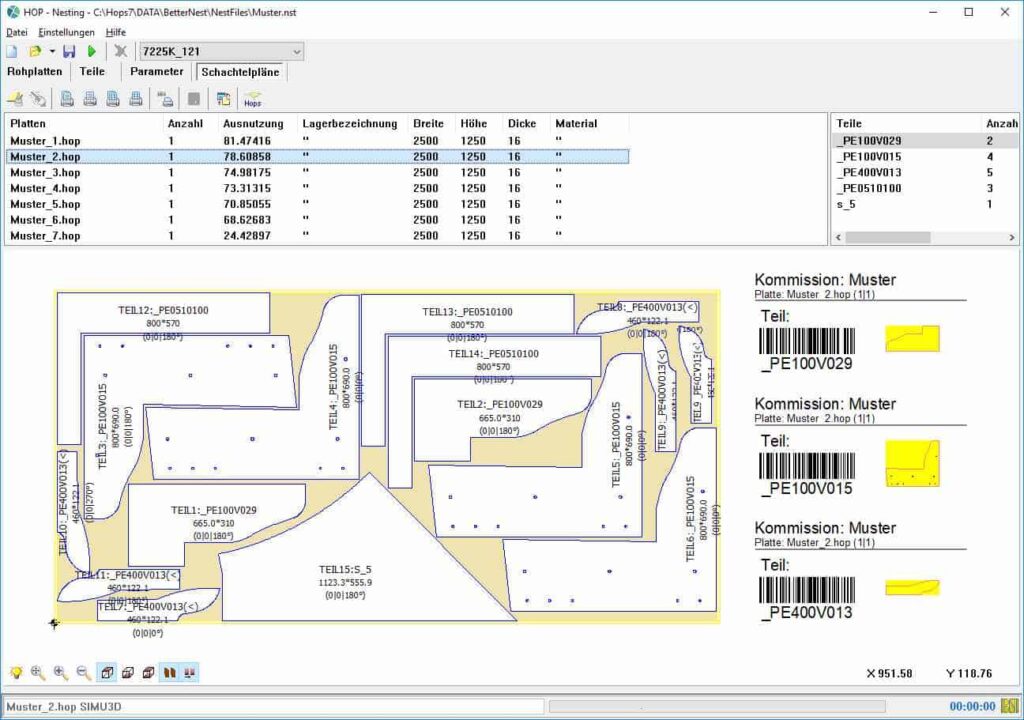

BETTERNEST

BETTERNEST

This automatic nesting module tries to bring as many parts as possible to a previously defined raw board by preset rotation, mirror and sorting properties. The components can of course be variable and can be imported from a list of ERP and PPS systems. The system optimizes the processing so that the components are held with the best possible hold by the vacuum. Machining on both plate sides is possible.

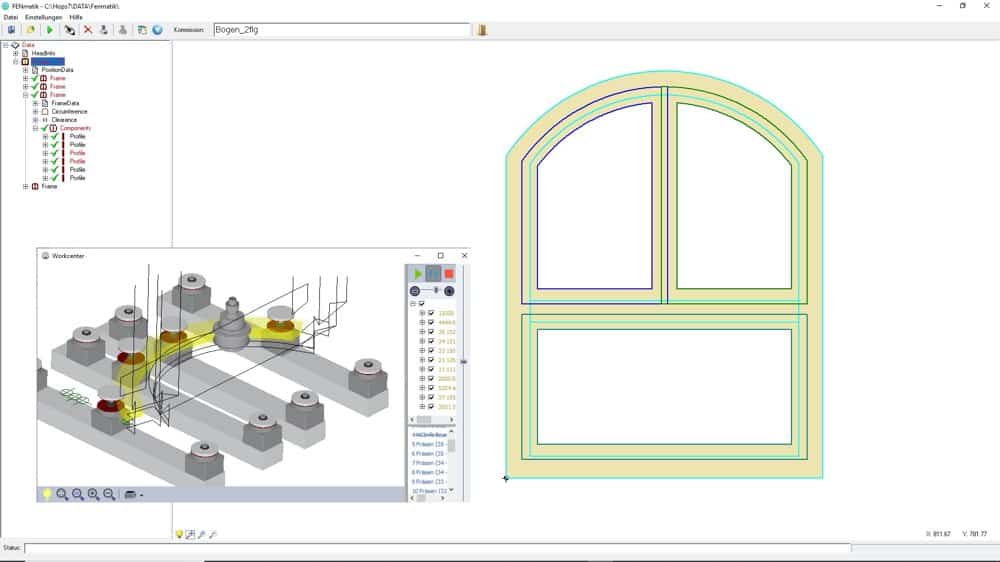

FENmatic, powerful solution for window design and production.

FENmatic, powerful solution for window design and production.

The use of CNC technology in door, window and façade technology means that there are virtually no limits to the form and complexity of connections and fittings.

The automatic transfer of constructions from window construction programs means that the generation of all necessary machining operations is only a matter of a few seconds. The assignment of machining macros in NC-HOPS ensures the flexibility and openness of the system. The calculation of the clamping positions and document plans on the machine is fully automatic.

FENmatik was developed for the preparation of order data from window construction programs. The components such as doors, windows and façade elements recorded in this program are read into a production explorer on a commission basis and visualized with the profile designation and fitting type.

The profile and fitting machining is stored as machining macro with the standard functions of NC-HOPS. This means that machining strategies dependent on the profile are also taken into account in program generation.

All profile and contour definitions provided by the window program can be processed by FENmatik cnc-technically, regardless of whether is used or not.

Keywords:

-doors, windows, facades

-multi wing

-straight, round, oblique

-zinc plated, dowelled, tapped

-Fittings all around

Thanks to the use of CNC technology in door, window and façade technology, there are hardly any limits in terms of form and complexity. Due to the automatic production organization with FENmatik for NC-HOPS, the transfer of customer orders to the CNC machine is a matter of minutes.

ANOPTI visualizes the operator at the machine the blanks to be coated. The machine table is occupied with as many workpieces as possible. Optimized machining minimizes tool change times and traverse paths. The automatic clamp calculation determines the positions of the clamps before and after reclamping in relation to the profile, thus ensuring an efficient production process. Complete machining in one clamping.

NC-HOPS as an innovative, powerful program, gives the user the opportunity to design his product creatively and easily.

Registers combine the functions into machining groups. This enables the required machining operations to be quickly found.

Extensive functions and the possibility to add your own macros offer optimal integration into the production process.

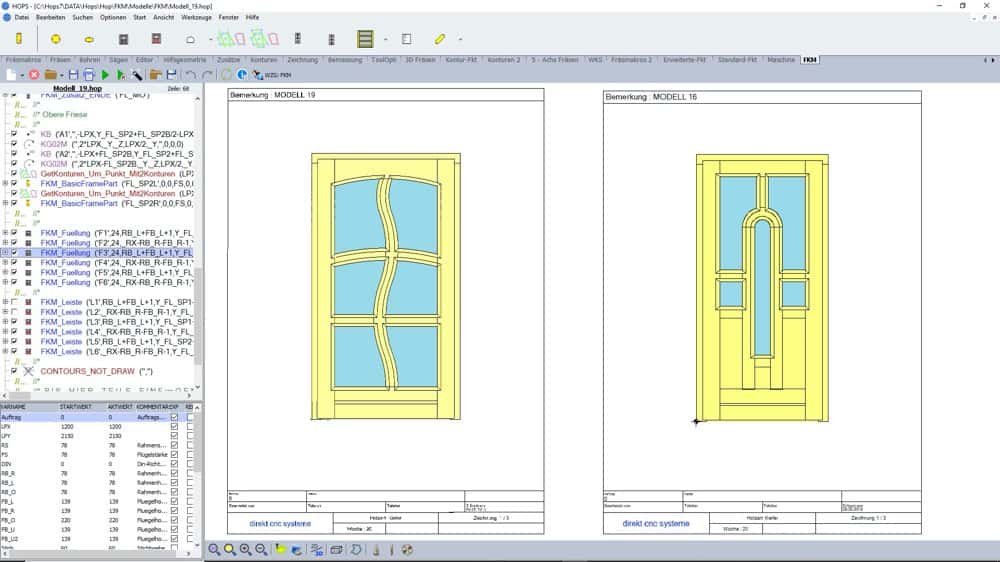

FENtura, the solution for flexible door design.

FENtura, the solution for flexible door design.

The option module FENtura extends the functionality in NC-HOPS to define frame parts in any geometry. By inserting the frame parts and by defining fillings and light cut-outs, the user can define any type of front door as well as special windows. Size, frame widths and bevels remain fully variable in their characteristics.

FENtura does not rely on a restrictive library of door types and allows with free forms new designs and arbitrary partitions to be created.

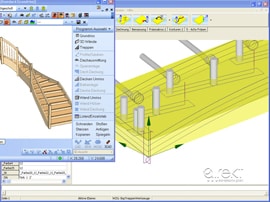

SEMA Import

SEMA Import

The automatic transfer from the SEMA stair construction guarantees the preparation of the stair workpieces in seconds for 3, 4 and 5-axis machines. The machining operations refer to machining macros which are assigned by NC-HOPS after a component analysis.

The NC programs required for staircase production are generated in seconds. Setup aids such as projection lasers (Look SL-Laser)or suction cup positioning are also supported.

(The SEMA Stair Construction is a product of SEMA GmbH Computer Software und Hardware-Vertrieb, 87499 Wildpoldsried, Germany).

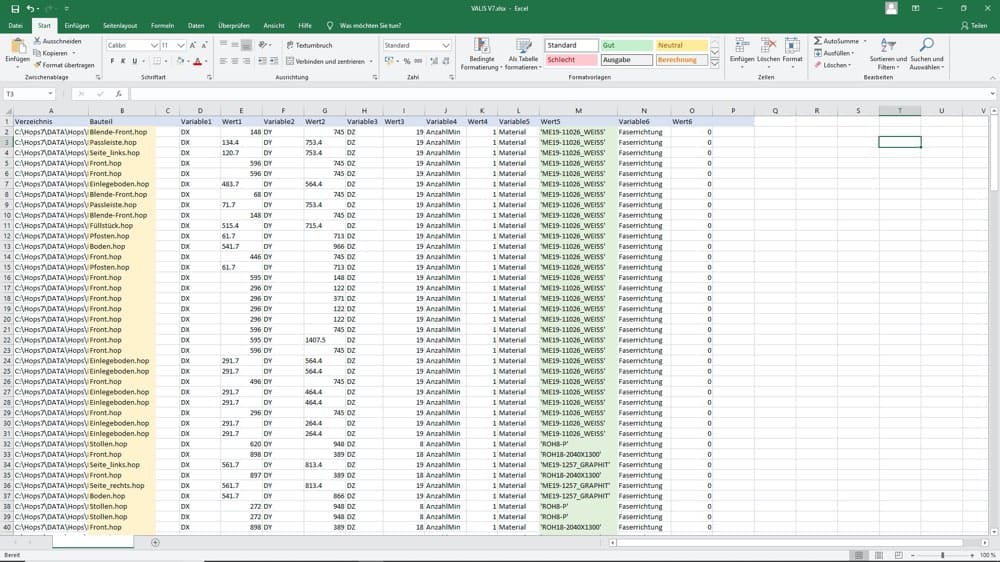

VALIS BOM transfer

VALIS BOM transfer

With VALIS, NC-HOPS provides the interface to your ERP and parts list system and enables the CNC machine data to be generated controlled by production planning. Capacity bottlenecks of machines can also be taken into account and programs can be distributed to different machines. Optimizations and feedback to the order system guarantee the integration of a machine into the production process.

In connection with the professional engineering of Direkt cnc-system gmbh and our partners, the ideas and goals of our customers can be realized with proven standard software, often proven competence, and integration into operational processes. Test us…

NC-HOPS WorkCenter

NC-HOPS sets another innovation with the WorkCenter user interface, which displays the stop situation and the machine table with clamping devices.

This program supports the machine operator by graphically setting up the part variants created in NC-HOPS or directly placing DXF drawings on them. The optional automatic calculation of the suction cup positions provides safety and speed during set-up.